The Grundomat soil displacing hammer provides a trenchless method to ground stabilisation. This method is great for areas of limited access and noise restrictions as installations do not require large trenches for placement.

Technical Info

Diameter: 100mm.

Depth: 9m.

Ground Condition: Displaceable soils such as sand, loam and gravel.

Benefits

Minimal noise and disruption.

Cost effective piling solution.

Accurate drilling powered by compressed air.

Pneumatically operated, self contained, reciprocating piling hammers.

Minimal space required for operation; fits through doorways for internal use.

Process

Grundomat piling a cost effective and versatile solution for small ground stabilisation projects.

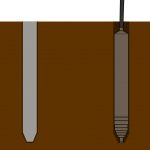

THE GRUNDOMAT

Compressed air is propelled through the air line and forces the piston against the rear of the chisel head. A nominal steel casing is used with the Grundomat, the pre-tensioned steel spring retracts forcing the chisel head forward independently of the main casing. The stepped-cone head enables accurate bore holes.

VERTICAL BORING

The continuous force thrusts the main casing ahead so the device follows the same path set out by the chisel head. Once the required depth is achieved, the Grundomat reverse mechanism extracts it from the hole and the mini pile is filled with concrete.