Rotary bored piles are ideal for inconsistent or tough ground conditions. Once each pile is bored, the concrete is mixed to accommodate the ground conditions to provide an effective retention solution for the final structure. Secant piled / contiguous piled walls are constructed by a series of bore holes with a designed spacing or gap.

Technical Info

Diameter: 450mm – 1500mm.

Depth: 30m.

Ground Condition: hard ground.

Benefits

Large diameter piles.

Supports greater loads.

Effective in hard ground where CFA can’t penetrate.

Full pile reinforcement framework can be achieved.

Casing stabilised structures for greater depths.

Process

A large rig is used to construct large diameter piles using the rotary method. Greater depths are achieved due to the ability to secure the pile throughout the structure with a temporary casing.

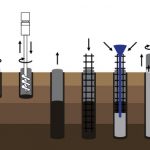

INSTALLATION

A solid stem rotary auger is drilled into the ground attached to a kelly bar to reach significant depths. A temporary casing is placed within the hole to prevent the structure collapsing in on itself. Excess spoil is removed by extracting the auger and shaking off the loose soil, this is repeated until depth is achieved.

FRAMEWORK

Once the temporary casing has been extracted, a reinforcement cage is inserted into the open pile structure. Concrete is then pumped into the borehole and cures with the wire reinforcement framework inside; creating a stronger pile structure.